POM-30, POM-40, POM-60, POM-80, POM-100

Downloads

The following paragraphs describe just a few of the many installations where POM blenders have been used successfully. The main feature that these applications have in common is that two dissimilar gasses needed to be blended at an adjustable ratio.

The AES POM blenders can blend any two or more gasses safely and reliably.

Sample Applications (Click the links for more information.)

Digester Gas Augmentation System

Situation:

Waste Water Treatment Plants produce "Digester Gas" (DiG) as a by-product of the waste water treatment. The DiG is used as fuel for multiple reciprocating internal combustion engines to drive air blowers and/or electric generators, or as fuel for boiler plants.

Periodically (for example during sludge removal), the DiG production does not match the consumption of the engines or boilers. This is typically handled by turning off one or more engines, which invariably leads to considerable amounts of excess DiG (more than the engines or boilers can consume, but not enough to add another engine). The excess DiG must be flared off to avoid pressure build-up in the digesters.

Efforts are now being made to eliminate the waste of energy (the flaring off of the excess DiG), and instead to add "just enough" DiG replacement gas to allow the operation of an additional engine or boiler.

Solution:

Installation of a POM blender that generates a NatGas/Air blend with properties that match the properties of the Digester Gas.

Operation:

The POM blender is supplied with air from a high-efficiency blower and with unregulated NatGas (10...50 psi). The blender discharges the DiG replacement gas at a higher pressure than that of the DiG (keeps the blender and the piping system small = less expensive). A "Tie-In Regulator" monitors the pressure in the gas supply line from the digester to the engines/boilers. If the DiG production is less than the consumption of the engines/boilers, the resulting loss of DiG pressure is detected by the Tie-In Regulator, causing it to open and to inject "just enough" DiG replacement gas to meet the demand of the engines/boilers, avoiding the need to flare off any DiG.

When the pressure in the digesters recovers, the Tie-In Regulator closes and the engines/boilers are only supplied by DiG.

Digester Gas Enrichment and Backup

Situation:

Waste Water Treatment Plants produce "Digester Gas" (DiG) as a by-product of the waste water treatment. The DiG is used as fuel for reciprocating internal combustion engines to drive air blowers and/or electric generators. The air from the blowers is used in the digester process; the electricity from the generators is used in the plant; excess electricity is sold to electric utility companies.

The heating value of the DiG depends largely on the type of waste that is being processed, and can therefore vary widely. These variations require the engines to be set up in a very "forgiving" mode, resulting in diminished efficiency and increased exhaust gas emissions.

Occasionally, the supply of DiG is interrupted due to equipment maintenance. This leaves the engines without fuel, which leaves the digester process without the air from the blowers, which is needed to stimulate and boost the digester process.

Solution:

Both goals, stabilization of the properties of the DiG as fuel for the engines, and backup fuel supply for times when DiG is unavailable, can be covered with the Installation of a single POM blender with Automatic Gas Properties Control (AccuBlend™).

Operation:

The POM blender is supplied with NatGas, with Digester Gas, and with Air.

If DiG is available from the waste water treatment process, the POM blends NatGas and DiG at a varying ratio that results in very stable fuel gas properties (Calorific Value) for the blower/generator engines.

If DiG is not available from the waste water treatment process, the POM blends NatGas and air at a ratio that results in a mixed gas that allows the blower/generator engines to operate at their highest efficiency with the lowest possible emissions.

A gas analyzer at the outlet of the POM measures the properties of the NatGas/DiG or the NatGas/Air mixture.

If the gas analyzer detects a deviation of the gas properties from the desired values, the AccuBlend™ controller automatically adjusts the position of the piston in the POM, thereby changing the blending ratio, and re-establishing the desired properties.

BioGas Enrichment and NatGas Conditioning

Situation:

A small town in Europe is supplied with locally produced "BioGas" from an agricultural operation. The BioGas is used in private homes for cooking and heating, and by several industries for heating and process. The heating value of this BioGas is slightly (~10%) below the heating values of normal NatGas.

For most of the year, the BioGas production is sufficient to supply all homes and all industries with gas. However, in winter the gas consumption is frequently greater than the BioGas production, and in summer the BioGas production is occasionally greater than the usage in this town.

Challenge:

Provide a solution that supplies the additional gas in winter; Provide a solution that avoids wasting excess BioGas (excess BioGas used to be flared off) by raising the heating value of the excess BioGas in summer so that it can be re-injected into the regional high-pressure NatGas grid.

Solution:

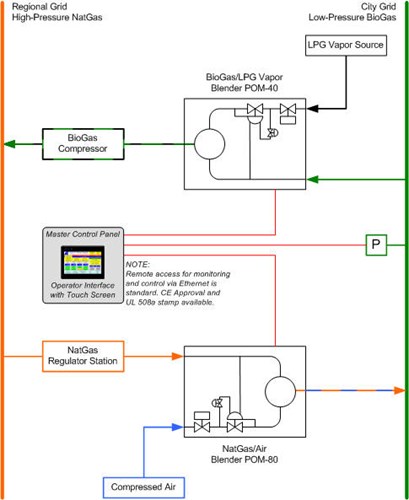

Install POM blender to reduce the heating value of NatGas from the regional high-pressure grid so that it is compatible with the properties of BioGas, and inject it into the city grid at times when the BioGas production is interrupted or is insufficient to meet the demand. Install a second POM blender to increase the heating value of the excess BioGas in summer so that it is compatible with the properties of NatGas and can be re-injected into the regional high-pressure NatGas grid.

Operation:

When the control system detects that the pressure in the low-pressure city grid increases above an adjustable setpoint (indicating that BioGas production exceeds consumption), the BioGas/LPG POM blender is turned ON automatically. BioGas from the city grid is blended with LPG vapor to increase its heating value, is compressed, and then re-injected into the high-pressure regional NatGas grid.

The BioGas blender stays online until the pressure in the city grid has fallen below a second adjustable set-point and then turns itself automatically off.

When energy consump-tion exceeds the available BioGas, the pressure in the city grid will fall below an adjust-able setpoint. This is monitored by the control system, which turns the NatGas/Air blender ON.

The NatGas/Air blender draws NatGas from the high-pressure regional grid, blends it with air to reduce its heating value, and injects it into the low-pressure city grid to provide the balance of gas demand.

The NatGas/Air blender stays ON until BioGas production is sufficient to raise the city grid pressure above an ad-justable setpoint.

BioGas/LPG blender and NatGas/Air blender are always "ready to go" and do not require on-site human intervention to start producing gas. The entire system is monitored remotely and can also be started manually through commands from the remote site.

Landfill Gas Backup

Situation:

The dryers in the paint shop of an automotive manufacturing plant are supplied with low-BTU Landfill Gas (LFG) as the primary fuel source.

Occasionally, the supply of LFG is interrupted due to equipment maintenance at the landfill site. Since the paint process is crucial to the continuous production output of the plant, a backup gas source is needed.

Solution:

Installation of a POM blender with Automatic Gas Properties Control (AccuBlend™).

Operation:

The POM blender is supplied with NatGas and with Air. The POM is pre-set to a blending ratio that results in highly "diluted" NatGas/Air mixture with a CV that resembles the properties of LFG. A GraviBlend®-3 gravitometer at the outlet of the POM measures the properties of the NatGas/Air mixture.

If the gravitometer detects a deviation of the gas properties from the desired values, the AccuBlend™ controller automatically adjusts the position of the piston in the POM, thereby changing the blending ratio, and re-establishing the desired properties.

The system is "always-ON". Two Fisher 1098EGR regulators monitor the pressure in the LFG supply line. If the pressure drops below an adjustable setpoint, the first regulator starts opening and begins injecting NatGas/Air into the fuel gas line to the paint shop. If the first blender is unavailable (i.e. for turned off for maintenance), the second regulator, which has a slightly lower setpoint, takes over. The transition from LFG to NatGas/Air, and from Blender 1 to Blender 2, is fully automatic and un-noticeable at the paint shop.

Natural Gas Stabilization

Situation:

A manufacturing line for tempered glass (TV picture tubes) is supplied by NatGas with fluctuating heating value (Calorific Value, CV). The fluctuations are significant enough to upset the production results.

Solution:

Installation of a POM blender with Automatic Gas Properties Control (AccuBlend™).

Operation:

The POM blender is supplied with NatGas and with Air. The POM is pre-set to a blending ratio that results in slightly "diluted" NatGas/Air mixture with a CV that is acceptable to the process. A Calorimeter at the outlet of the POM measures the CV of the NatGas/Air mixture.

If the Calorimeter detects a deviation of the CV from the desired value, the AccuBlend™ controller automatically adjusts the position of the piston in the POM, thereby changing the NatGas/Air blending ratio, and re-establishing the desired CV.

If the CV of the NatGas as supplied to the plant is always higher than the minimum acceptable CV, the POM blender would always "dilute" the NatGas with Air.

If the CV of the NatGas as supplied to the plant could fall below the minimum acceptable CV, the POM blender can be switched to "Enrichment Mode". In this mode, the air supply is turned off, and is replaced with a supply of BTU-rich gas, for example LP vapor. As before, the NatGas and the LP vapor will be mixed by the POM blender to achieve the desired CV. The Calorimeter will again be used to provide a feedback signal to the AccuBlend™ controller to make adjustments to the blending ratio if and when required.

Note:

The switch from "Dilution" to "Enrichment" can be initiated manually by the operator, or can be accomplished fully automatically (without operator interaction).

Coke Oven Gas Replacement

Situation:

A steel mill operates their own coke plant. Coke Oven Gas (COG) is a by-product of the Coke-making process and is used to fuel the process.

Occasionally, the Coke batteries have to be shut down for maintenance and repairs. To start the batteries back up again, COG is required. However, since the batteries are shut down, no COG is being generated.

Solution:

Installation of a POM blender with Automatic Gas Properties Control (AccuBlend™).

Operation:

The POM blender is supplied with NatGas and with Air (or Nitrogen). The POM is pre-set to a blending ratio that results in highly "diluted" NatGas/Air mixture with a CV that resembles the properties of COG.

A Calorimeter at the outlet of the POM measures the CV of the NatGas/Air or NatGas/Nitrogen mixture.

If the Calorimeter detects a deviation of the CV from the desired value, the AccuBlend™ controller automatically adjusts the position of the piston in the POM, thereby changing the blending ratio, and re-establishing the desired CV.

Click on the thumbnail for a 46 kB PDF with a simplified P&ID for a triple-blender COG system. The system can be operated in "Sweetening-Only" mode, or in "Sweetening plus Augmentation/Replacement" mode.

The system is sized for 1,800,000 scfh (810 MMBTU/h) and has three POM-80 blenders that are staged to provide a system flow rate turndown of 1% to 100%.

Other Non-Standard Blending Applications

The POM blenders can be used for the blending of any two dissimilar gasses at (almost) any blending ratio. In standard POM configurations, the gasses must be compatible with Carbon Steel, Brass, Aluminum, and Buna N or Viton®.

For more corrosive applications, POM valve and other components in the gas streams can be manufactured from Stainless Steel or other corrosion-resistant materials.

Please contact the factory with your specific requirements.